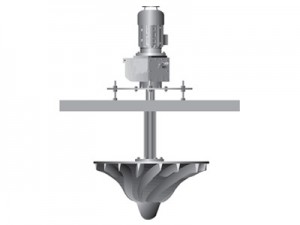

There are plenty of features to look at, like the three-lobes blower with helical casing offers a virtually no noise, no vibration operation. The most impresive feaure is that there is no oil mixing, so the air obtained is clean, with no spraying of oil mist to soil the environment, but how much does it cost to replace an oil pump if this oil system ends up failing? A few other features are: Normal Pressure Ranging – 0 ~ 80kPa Aeration systems perform two functions simultaneously: The low speed aerator designed for optimum stirring and oxygenation of sewage water is particularly used in fixed version The solidly-built components have been selected to guarantee a long life with a reduced maintenance. The solidly-built low speed turbines consist essentially of a rotor attached to a geared-motor by means of connecting shaft. Thanks to a flask incorporated into the geared-motor, the whole unit can be fixed on a concrete walkway or a metal framework. Oxygenation efficiency Efficiency between 1.6 and 2.4kgO2/kWh depending on operation conditions. Power Ranging from 2.2kW – 55kWANLET Blower

Features

Bore size available: 20mm ~ 400mmApplication of Blowers

Water Treatment

Incinerating

Composting through fermentation of cattle excrement

Dewatering

Aeration

Sand Blasting

Press machinery

Pneumatic Convenying

Application

PAD – a PUMPEN branded series bubble diffuser are mainly applied in treatment of water from:

And for other uses like:

A research program has been made to optimize the essential parameters of air diffusion through a flexible membrane.

Advantages & Technical Specification

Technical Parameters

Materials:

Tube diffuser also available

Item

PAD-300mm (12')

Working oxygen volume (Nm3/h)

0 ~ 6

Recommended oxygen volume (Nm3/h)

6 ± 1

Bubble size (mm)

0.8 ~ 2.1

Service area (m2/piece)

0.65 ~ 0.95

Oxygenation dynamic efficiency (kgO2/kwh)

8.5

Oxygen transfer efficiency (kgO2/kwh)

0.45~0.75

Oxygen utilization ratio (%)

≥ 30

Drag loss (mmH2O)

≤ 300

Membrane Material / Tray Material

EPDM / ABS

The HYDRO-CHEK air diffuser is the result of an extensive research and development program. It combines simplicity of design and operation with quality construction to provide efficient, economical and trouble-free aeration throughout new and existing water treatment systems.

The Patented ‘down-flow’ design puts air flow orifices in the diffuser body, not in the air check diaphragm. It also preserves the diaphragm’s structural integrity for significantly extended diaphragm life and eliminates the problems caused by sediment that could otherwise settle in diaphragm orifices. This down-flow design also maximizes the shearing of the air bubbles as they emerge from the orifices and turn upward around the perimeter of the diffuser.

The HYDRO-CHEK air diffuser uses the positive action of the flexible air check diaphragm to prevent backflow. The diaphragm distends during aeration to allow air through the diffuser body orifices. When the airflow is stopped the diaphragm instantly contracts and is force seated against the diffuser body by the water pressure in the tank. In this closed position, liquid backflow is prevented from entering and clogging the diffuser or air manifold.

The HYDRO-CHEK air diffuser is the result of an extensive research and development program. It combines simplicity of design and operation with quality construction to provide efficient, economical and trouble-free aeration throughout new and existing water treatment systems.

The Patented ‘down-flow’ design puts air flow orifices in the diffuser body, not in the air check diaphragm. It also preserves the diaphragm’s structural integrity for significantly extended diaphragm life and eliminates the problems caused by sediment that could otherwise settle in diaphragm orifices. This down-flow design also maximizes the shearing of the air bubbles as they emerge from the orifices and turn upward around the perimeter of the diffuser.

The HYDRO-CHEK air diffuser uses the positive action of the flexible air check diaphragm to prevent backflow. The diaphragm distends during aeration to allow air through the diffuser body orifices. When the airflow is stopped the diaphragm instantly contracts and is force seated against the diffuser body by the water pressure in the tank. In this closed position, liquid backflow is prevented from entering and clogging the diffuser or air manifold.

Technical Specification

Maximum capacity

12 CFM (20.4m³/hr)

Diameter

100mm (4’)

NPT Threads

3/4”

Materials

Body

Celcon plastic

Diaphragm

EPDM-base rubber

Retaining Ring

Polypropylene plastic

SURFACE AERATORS

Low Speed Surface Aerators – OPTIMUM OXYGENATION AND STIRRING