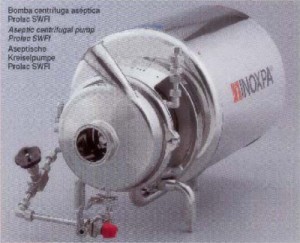

Brand: Inoxpa

Application

The Hydinox SE pump is a centrifugal pump manufactured in stainless steel and with a shrouded motor.

Its sanitary and cost-efficient design makes it perfect for the dairies, beverages, food-processing, pharmaceutical and fine chemical industries.

Design and features

- Casing manufactured with cold-formed plate

- DIN connections (standard)

- Open impeller manufactured with stainless steel investment casting

- Mechanical seal according to DIN 24960 L1K

- AISI 304 engine shroud

- Adjustable stainless steel legs

- Pump certified according to 3A sanitary standards

- IEC B34 engines, IP 55, F-class insulation

Materials

- Parts in contact with pumped media: AISI 316L

- Other parts: AISI 304L

- Gaskets (standard): EPDM segun FDA

- Mechanical seal (standard): C/SiC/EPDM

- Inside surface finishing

- Outside surface finishing: Mirror polished

Options

- Mech. seal in C/St. St and SiC/SiC

- Gaskets in FPM (Viton®) and PTFE

- Self-priming casing

- Drainage connection

- Connections: Clamp, SMS, RJT

- Motors with additional protection

- Trolley and/or electric panel

Application

The Aspir pump is a sanitary, side-channel, self-priming pump suitable for use in the food-processing, pharmaceutical and chemical industries.

It is specially designed for pumping materials containing air or gas, and it can also be used for negative suction with prior priming as well as with filtration equipment.

It cab be used with wine, oil, syrups, volatile products such as alcohol, acetone and other solvents, or with products at temperatures close to boiling point. However, the main use of this pump is for CIP return.

Design and features

- Casing manufactured with cold-formed plate.

- Stainless steel investment casting inletbody and venturi.

- Star-shaped floating impeller manufactured with investment casting technology.

- External mechanical seal that prevents contact between the springs and the pumped fluid.

- Very robust stainless steel-cast lantern.

- Pump support of stainless steel.

Materials

- Parts in contact with pumped media: AISI 316

- Other parts: AISI 304

- Gaskets (standard): EPDM segun FDA

- Mechanical seal (standard): C/SiC/EPDM

- Surface finishing: Electro polished

Options

- Mech. seal in C/St. St and SiC/SiC

- Gaskets in FPM (Viton®) and PTFE

- Drainage connection

- Connections: Clamp, SMS, RJT

- Bypass

Application

The Estampinox EFI pump is a stainless-steel centrifugal pump for decanting water and other fluids.

It is designed to cater for the needs of all the Auxiliary Services in the Food-Processing, Chemical, Pharmaceutical, and Wine-Making industries, among others.

Design and features

- Casing manufactured with cold-stamped sheets.

- BSP connections (standard)

- Open impeller manufactured with cold-stamped stainless steel sheets or investment casting (according to model).

- Inside mechanical seal.

- Simple parts and easy maintenance.

- Engine according to IEC B34 standards.

Application

The DIN-FOOD pump is a sanitary, high-flow centrifugal pump designed to cater for a hitherto unfulfilled need in the food-processing and chemical/pharmaceutical industries.

Its applications include processes in the brewing, diaries and beverages industries in general, as well as ultra-filtering processes. It can also be used in the textile industry and in special processes in the chemical, cosmetics and pharmaceutical industries.

Design and features

- Casing with volute manufactured with 8mm cold-stamped sheets.

- Sanitary flanges according to DIN 11864-2.

- Double-curvature impeller with blades on the rear side

- Axial adjustment of the impeller

- Sanitary mechanical seal

- Fully-drainable pump

- Designed according to 3A and EHEDG standards

- IEC B3 engines (B35 in monobloc models), IP55, F-class insulation

Application

The RVS pump is a high efficiency pump. Due to the helicoidal design of the impeller, it allows to pump delicate food stuff wihtout damaging it, e.g. solid particles suspended in water (prportion: 40% to 60%).

It is intended for pumping pieces of fruit or whole fruits, olives, mushrooms, orange segments, vegetables, fish, etc.

In comparison with the RVC_XX range, the RV_XXR pumps are provided with a bearing support in the lantern for work with viscous products and for applications provoking an increased axial stress.

Design and features

- Close-coupled design

- Helicoidal impeller

- Pump casing with drain port

- Pump casing with eccentric volute

- High efficiency (65 – 70%), low power consumption

- Motor: IEC B35 1500rpm

- Mechanical seal: EN 12756 (DIN 24960 L1K)

- Connection: DIN 11851

- Bearing support integrated into the lantern (RVS-80R and RVS-100R)

- Maximum particle size: 75mm

- 3A certified pump

Materials

- Parts in contact with the product: AISI 316L

- Lantern: AISI 316L

- Other st.st. parts: AISI 304

- Bearing support (RVS_XXR): GG 25

- Gaskets: EPDM according to FDA 177.2600

- Mechanical seal (standard): SiC/SiC/EPDM

- Inside surface finish: Ra ≤ 0.8µm

- External surface finish: Mirror polish

Options

- Connections: SMS, Clamp, Macon, Garolla, FIL, RJT

- CE control panel with 10m cable and plug

- St.St. trolley

- Remove control

- Motor shroud

- Motor with a frequency converter

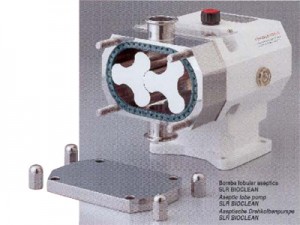

Application

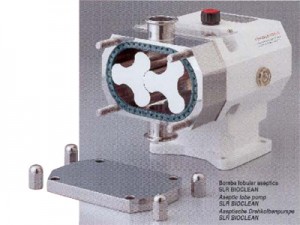

The SLR pump is lobular rotating positive displacement pump of a sanitary design suitable for use in the dairies, food-processing, beverages, pharmaceutical and fine chemicals industries.

The pump is perfect for managing all kinds of fluid, of either low or high viscosity, in the food-processing, dairies and cosmetics industries, as well as for filtering and bottling applications. Fluids containing fragile solids such as junket, can be pumped without damage thanks to the specially designed lobes.

Design and features

- Bare-shaft construction.

- Casing and rotors in stainless steel investment casting technology.

- Tri-lobe rotors.

- Health-safe design of the attachment of the rotors.

- DIN connections (standard).

- Sanitary mechanical seals.

- Easy cleaning and maintenance.

- Pump certified according to 3A sanitary standards.

Materials

- Parts in contact with pumped media: AISI 316L

- Support: GG-15

- Gaskets (standard): EPDM segun FDA

- Mechanical seal (standard): C/SiC/EPDM

- Inside surface finishing: Ra ≤ 0.8µm

- External surface finishing: Mirror polished

Application

The RF pumps is a flexible-impeller pump. Because of their design, these pumps are reversible and self-priming that can suction from a maximum heights of 5 meters. This type of pumps can pump materials of both low and high viscosity, as well as materials containing particles or gases.

Their main uses include pumping in dairies, edible oils, wine concentrates and beverages in general. They can also be used with viscous food products such as jam and marmalade, confectioner’s custard, as well as cosmetic products such as soap, gels, toothpaste, and cosmetic creams. Other applications include the dying, textile and chemical industries.

Design and features

- Easy maintenance

- Machined stainless steel investment casting casing

- Connections DIN 11851

- Motor according to IEC standards. B34, 1500 rpm, 3ph, 230/400 V, 50Hz, IP55

- External single mechanical seal

- Double flat drive of the impeller

- Bare-shaft o closed-coupled construction.

- Ra<0.8µm surface finishing.

- White painted.

- Reversible and self-priming

Materials

- Parts in contact with pumped media: AISI 316L

- Lantern and bearing support: GG-22

- Other parts: AISI 304

- Impelleter: Neoprene

- Gaskets (standard): NBR

- Mechanical seal (standard): Cer/C/NBR

Options

- Connections: SMS, Clamp, Macon…

- Lip seals

- SiC/C and SiC/SiC mechanical seals

- Motors with other protections

- Stainless steel trolleys

- Electric panel with 10m cable

- 1000 and 750 rpm motors

- 2 speed motors

- Motors with frequency converter

Application

The KS/KST/KSF pumps are sanitary progressive cavity pumps. Due to the design, they are self-priming and reversible pumps that can suction from a maximum height of 7 meters. These types of pumps transfer products of low and high viscosity, as well as products containing particles.

They are widely used to pump edible oils, wine, concentrates and beverages in general as well as viscous food products such as jam and marmalade, paste pate, melted cheese, etc. In the cosmetic industry, these pumps are used in applications involving various cosmetic products such as soap, gels and creams.

Design and features

- Bare shaft, close-coupled construction, model with hopper.

- EN 12756 L1Ksingle internal mechanical seal

- DIN 11851 standard connections.

- Open transmission (hygienic design).

- Painted white

- 3A certified pump

- Excentric outlet

Materials

- Parts in contact with the product: AISI 316L

- Other stainless steel parts: AISI 304

- Lantern and bearing support: GG-25

- Stator: Black NBR (according to FDA 177.2600)

- Gaskets: NBR (according to FDA 177.2600)

- Mechanical seal: Cer/C/NBR

- Internal surface finish: Ra ≤ 0.8µm

- External surface finish: bright polish

Options

- Connections: clamp, flanges, SMS, etc.

- Double pressurized mechanical seal

- Packing gland

- Mechanical seals SiC/C and SiC/SiC

- Stators in black / white EPDM (according to FDA 177.2600) and white NBR

- Gaskets in EPDM (according to FDA 177.2600)

- Heavy-duty transmission

- Steel or stainless steel trolley

- Electrical panel

- Bypass pressure relief valve

- Cleaning port

Application

The Mixers are used to mix solids in liquids. In the food-processing industry, they provide a perfect solution for reconstituting powdered milk, making syrups, preparing brines, etc.

They can also be a solution for preparing solid-liquid mixtures in the pharmaceutical, cosmetics and chemical industries.

Design and features

- Simple and versatile assembly for quick and homogeneous mixing of a great variety of solids without contact with the air.

- Complete mixing with recirculation of the material.

- In some applications, it can be used in line, without recirculation.

- Sanitary design.

- Easy assembly and disassembly by Clamp connections.

- Cleaning can be carried out without disassembling the unit.

- Sanitary single mechanical seal.

- Standard hopper of 40l for M-226 and 50l for M-440

Materials

- Parts in contact with the media: AISI 316L

- Gaskets (standard): EPDM according to FDA

- Mechanical seal (standard): C/St.St/EPDM

- Inside finish: mirror polished Ra < 0.8µm

- Outside finish: Mirror polished

Options

- Dual cooled seal.

- Dual pressurized seal.

- Connections: DIN, SMS.

- Pneumatic actuator valve.

- 60l hopper.

- Screen in the mixing chamber.

- Drainage.

The new range of SWFI and SLR BIOCLEAN aseptic pumps by Inoxpa have been designed to satisfy the most rigorous demands of the pharmaceutical and biotechnological industry and sterile processes.

All the models are ultra hygienic and comply with SA standard. All the parts that come into contract with the product are made in AISI 316L and the elastometers comply with FDA requirements.

The new range of SWFI and SLR BIOCLEAN aseptic pumps by Inoxpa have been designed to satisfy the most rigorous demands of the pharmaceutical and biotechnological industry and sterile processes.

All the models are ultra hygienic and comply with SA standard. All the parts that come into contract with the product are made in AISI 316L and the elastometers comply with FDA requirements.

Brand: ITC

Fluids Dosing And Control

Electric dosing pumps for flows ranging from 2.5l/h to 2000l/h, and maximum pressure up to 20 bar.

Membrane and piston pumps specially designed for the dosing of all type of chemical products whether corrosive,

toxic or highly viscous, for water treatment applications, industrial processes, petrochemical industry and agriculture.

Manufacture material:

- Head : PP, PVDF, stainless steel, PTFE

- Diaphragm : reinforced PTFE

- Piston : Ceramic, PEUHMW

- Electric motor : 230/400, Vac 3Ph, 115/230 Vac 1Ph, 12/24Vdc

DOSTEC 40

- Diaphragm and piston dosing pumps

- Flows : 2.5-500 l/h

- Max Pressure : 20 bar

DOSTEC 50

- Diaphragm and piston dosing pumps

- Flows : 100-1200 l/h

- Max Pressure : 12 bar

Electromagnetic Diaphragm dosing pumps for flows from 0.5l/h to 9l/h, and maximum pressure up to 10 bar

Specially designed for water treatment, industrial processes, swimming-pool, agriculture.

Manufacture material:

- Head : PVDF

- Diaphragm : PTFE

- Power Supply : 115/230 Vac 1Ph, 12Vdc

DOSITEC-MP/MD

- Manual regulation by means of potentiometer

- Adjustable pulses from 0 to 100%

- Input for a level switch to stop the pump

DOSITEC-Q

- Proportional regulation by means of a digital signal

- Operating modes : Proportional to an external pulse

Overview

We are a renowned vacuum pump supplier in the industry. Our effort and continuous product improvement has enabled us to provide good support to our customer.

Application

Example of usage at vacuum pump:

- Drying

Vacuum drying of components or parts in the Industries after washing

- Food Packing

Used for packing perishable food such as vegetable and meat.

- Elimination of shaving chips

Powder and chips plastic which are produced during processing can be collected.

- Vacuum casting

Used as source of vacuum for V process casting.

Normal Pressure Ranging -10kPa to -50kPa

Bore Size Available: 65mm to 250mm

Normal Pressure Ranging -10kPa to -50kPa

Bore Size Available: 65mm to 250mm

Brand: Teral

Model: APL

Applications

- Drainage in the digestion tank

- Waste water, sump drainage

- Drainage of spring water and stagnant water in the construction field

- Dewatering for fish pond or basement and cellars

Features

- A precisely manufactured motor is achieved utilizing the highest standard of quality control. To ensure 100% quality manufactured motor with stable performance and highest efficiency. All rotors adopt heat treatment method for drive shaft assembling and stator winding impregnated with varnish and baked in industrial oven.

- Standard accessories include: VCT cable with an epoxy resin sealed water resistant cable base, Auto Cut motor thermal protector, double mechanical seals and lip seal design.

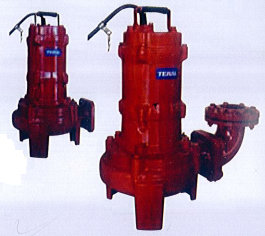

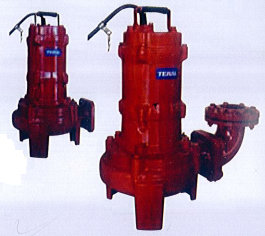

Brand: Teral

Model: ABO

Applications

- Drainage of sewage with solid in the city building

- Miscellaneous drainage and kitchen drainage

- Sewage management, accumulated water, septic tank, livestock farm

- Dewatering of waste water from the attenuation tank purifying tank and sewage tank in water treatment plant

- Drainage of other sewage with solid

Features

- International standard design: VCT cable, autocut, dry motor, silicon carbide mechanical seal, high grade cast iron offering highest quality and performance.

- Superior abrasion resistant mechanical seals made of silicon carbide to ensure the best seal effect.

- Oil seal mounted outside of seal chamber prevents solids build-up around seal surface.

- Compatible with Guide Rail System, which allows convenient remote installation and replacement of the pump without the need to enter the pit.

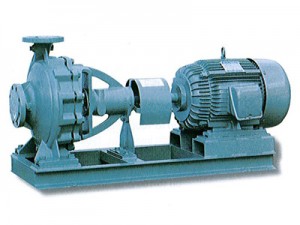

Brand: Hyosung Ebara

Single-suction Volute Pump (HES)

Features

- Standardized capacity and dimension, shows highest efficiency for any specifications.

Use

- Industrial water, farm irrigation, cold and hot water circulation in building. Fire lighting pump.

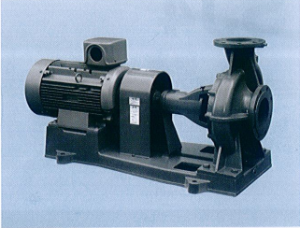

Brand: Teral

SJ4 model

Applications

- Hot and cold water circulation and general water supply

- Supply of industrial water and distribution of waterworks

Features

- Most versatile pump compliant with Japan Industrial Standards (JIS B8313).

- Low noise because of tetrapolar electromotor drive.

- Stable operation is possible within specifications with a wide water rate range.

- Easy disassembly and inspection in a simplified structure and by adoption of the B.P.O. (back pull-out) method.

- Robust structure for piping load with stable installation because of adoption of upright discharge.

- Simple and rigid structure based on rational design allows for reduction in costs, user friendliness, and stable operation.

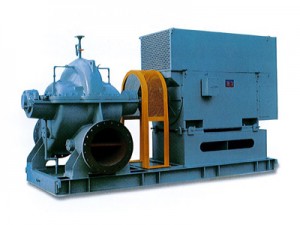

Brand: Hyosung Ebara

Double-suction Volute Pump (HDR)

Features

- Standardized design, wide scope of use and high efficiency.

Use

- City water supply, long-distance irrigation in farm, industrial water supply to various plants. Fire fighting pump.

Brand: Teral

DH series pump

Applications

- DH series pump is often used in the area of waterworks, irrigation and drainage pumping station, power station, industrial water supply system, and fire fighting.

Features

- Anti-flexible design tightening shaft sleeve.changeable motor position (no parts changing).

- Special designed flange guarantee pump standing.

Maximum allowable suction pressure is 1.6MPa.

Maximum allowable working pressure is 2.4MPa.

- Special designed seal body, commoner use, all series including 24 specs, only 3 kinds of shaft.

- Special designed bearing obx, shoter rotor shaft, long-life, lower noise, nice appearance.

Brand: Hyosung Ebara (Horizontal)

Multi-Stage Turbine Pump (HTM)

Features

- High-pressure pump with simple structure and high efficiency.

Use

- Boiler water supply, city water supply, industrial water, pressurized device, Fire fighting Equipment and facilities.

Brand: Teral

ASVM

Typical Applications

- Water Supply and Booster System

- Water Circulating and Processing System

- Boiler Feed and Condensate Return System

- Water Treatment and infiltration Analysis System

- Irrigation and Deaeration

- Industrial Washdown System

Applications

- Standard pumps are used in liquid transfer and hot/cold clean and softened water circulation and boosting. Stainless steel pumps are used in alkali, mineral and distilled water; swimming pool and chlorine solution. The allowable liquid temperature shall be reduced.

The new range of SWFI and SLR BIOCLEAN aseptic pumps by Inoxpa have been designed to satisfy the most rigorous demands of the pharmaceutical and biotechnological industry and sterile processes.

All the models are ultra hygienic and comply with SA standard. All the parts that come into contract with the product are made in AISI 316L and the elastometers comply with FDA requirements.

The new range of SWFI and SLR BIOCLEAN aseptic pumps by Inoxpa have been designed to satisfy the most rigorous demands of the pharmaceutical and biotechnological industry and sterile processes.

All the models are ultra hygienic and comply with SA standard. All the parts that come into contract with the product are made in AISI 316L and the elastometers comply with FDA requirements.

Normal Pressure Ranging -10kPa to -50kPa

Normal Pressure Ranging -10kPa to -50kPa